JCB Diagnostic Scan Tool

When it comes to material handling, construction, and agricultural equipment, there are few companies that can match the brand strength of JCB. A leading manufacturer in North America, JCB is known for its highly advanced systems and components, making for very operator-friendly machinery. Hence, great performance and performance boost comes as default.

If you have JCB equipment working for you, the JCB diagnostic tool should be a must-have to make sure that your fleet is always in peak performance mode. Timely diagnosis of faults with our Jaltest software and implementing quick corrective action will keep your JCB equipment always on the job.

This is more so as the JCB diagnostic kit is optimized for support across a wide range of JCB equipment models. These include JCB 506C, JCB 507-42, JCB 510-56, JCB 512-56, JCB 540-170, JCB 3CX (Loader Backhoe – in applicable MHE range), and more. Hence, whatever the model of your JCB equipment, our software, the JCB fault code reader, offers superior diagnostic results.

Apart from the JCB scan tool, our Jaltest maintenance software tool covers other critical machines like construction equipment, other makes of material handling equipment, trucks, marine engines, and others.

Request a Custom Demo VideoCutting-Edge Capabilities of the JCB Diagnostic Interface

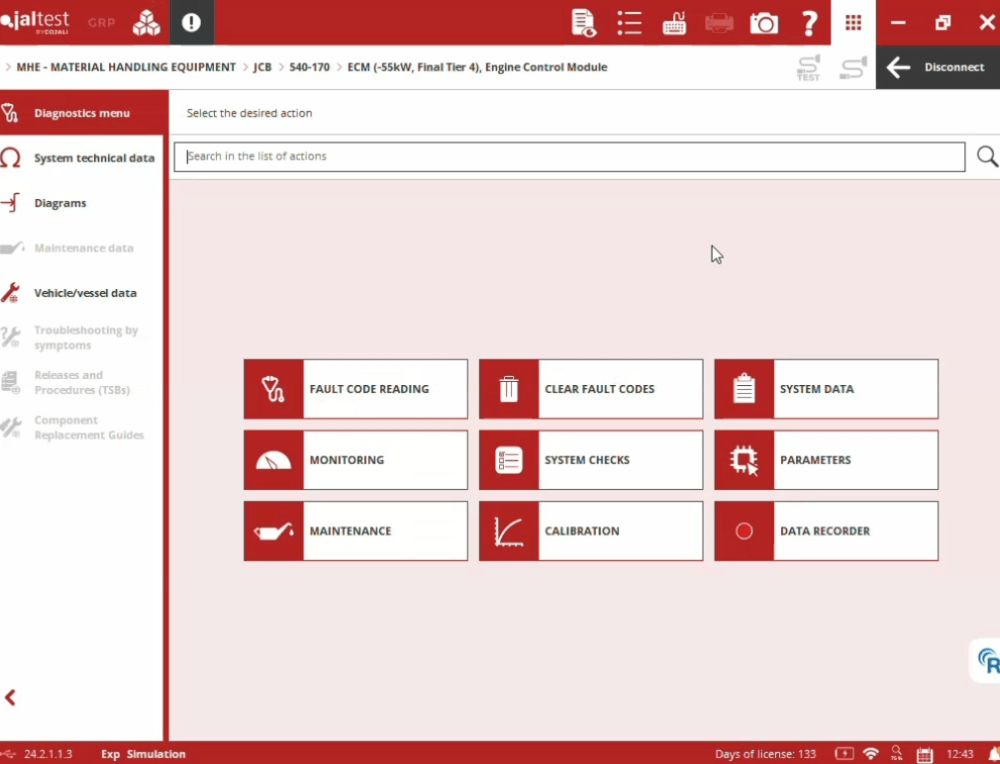

Our JCB trouble codes reader has cutting-edge diagnostic capabilities for several functions. You can read fault codes and clear them, carry out system checks and maintenance, monitor system data, set parameters, calibrate systems, actuate components, and more.

You are thus assured that your JCB equipment will always match the performance expected from it without downtime. Any issue that might crop up can be quickly resolved with our Jaltest software at dealer-level servicing standards before it becomes a major problem.

One of the critical functions of the JCB diagnostic interface is to identify and interpret fault codes and offer solutions to clear them. These fault codes will appear on your software laptop as soon as you connect it to the onboard computer of your JCB equipment.

Here are some examples of fault codes stored in memory from the JCB diagnostic codes reader.

- P0523-68: Engine oil pressure sensor, Voltage is too high. System event.

- P0116-64: Coolant temperature sensor, Over Temperature

- P0196-64: Engine Oil Temperature Sensor, Over Temperature

- P2BA9-F1: Insufficient AdBlue/DEF quality, Warning level 3

- P0341-00: Camshaft sensor.

Deep Coverage of JCB Systems and Components

The JCB trouble codes reader offers in-depth coverage of several systems and components of JCB material handling equipment.

Here is a quick look at some of the systems supported by the JCB diagnostic software.

Body Modules:

Transmission control unit (TCU), Lift and tilt systems, Instrumentation panel, Hydraulic control module, Safety interlock system

Common Engine Models:

JCB Dieselmax, Kohler KDI, Perkins 1104D / 404D, Cummins QSB Series

Transmissions:

JCB Powershift transmissions, Hydrostatic transmission systems, ZF transmission modules (where integrated in JCB units)

Hence, one JCB fault code checker has multi-functional capabilities and works equally effectively as a JCB hydraulic system check, hydrostatic transmission diagnostic tool, Perkins diagnostic tool, and more.

Jaltest JCB Engine and Transmission Diagnostic Software

The engine and transmission, as in all vehicles, power your JCB equipment, and our Jaltest software focuses greatly on always keeping them on the move.

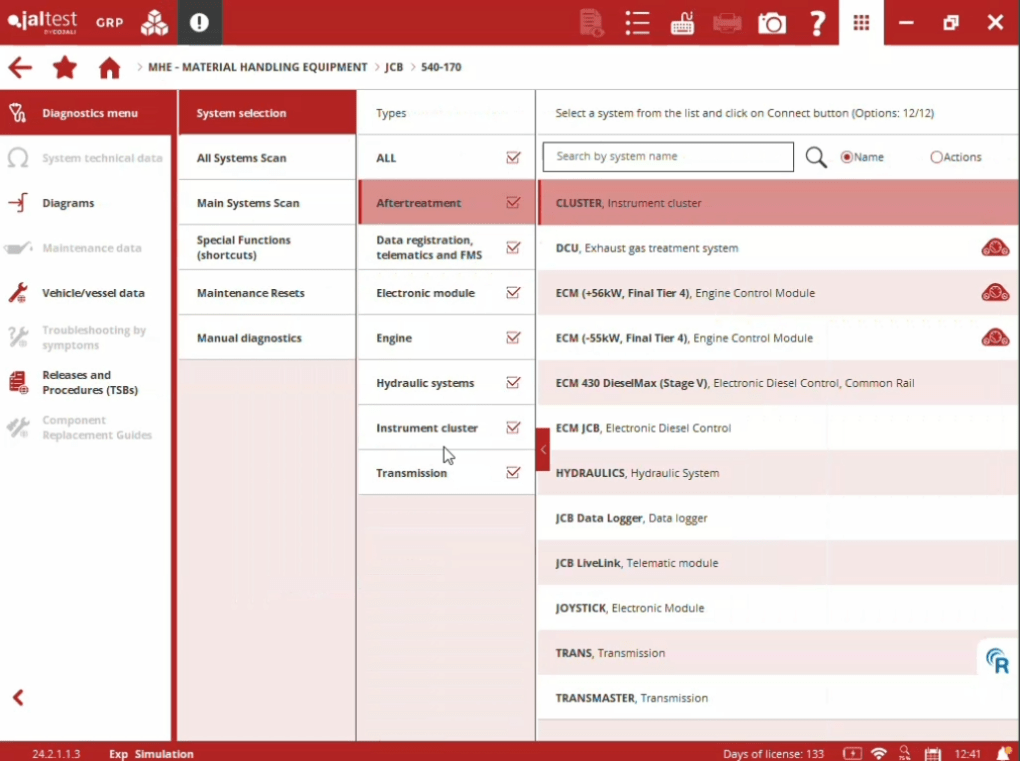

For engines, regardless of whether you need a Kohler KDI diagnostic tool, Perkins, or Cummins scan software, we have you covered. Simply select our diagnostic menu, choose the specific engine section, and you get several Engine Control Modules (ECMs) for cutting-edge diagnostics and fault clearance. For example, you get 56KW and 55KW, Final Tier 4 Engine Control Module diagnostics as well as ECM 430 that represents Electronic Diesel Control, Common Rail.

Additionally, go to the Special Functions (Shortcuts) and diagnose a lot of engine functions, such as the functioning of the Exhaust Gas Recirculation (EGR) valve, a critical component of internal combustion engines. From our software, you can system check the EGR valve and calibrate it. Other checks include the engine revolutions sensor in the camshaft and injector codes modifications.

Advanced diagnostics are also available for transmissions. Whatever JCB material handling equipment you might have, diagnostics are available for hydrostatic and electronically controlled drive systems integrated into JCB platforms and telehandlers.

All-Inclusive Diagnosis Of JCB Material Handling Equipment

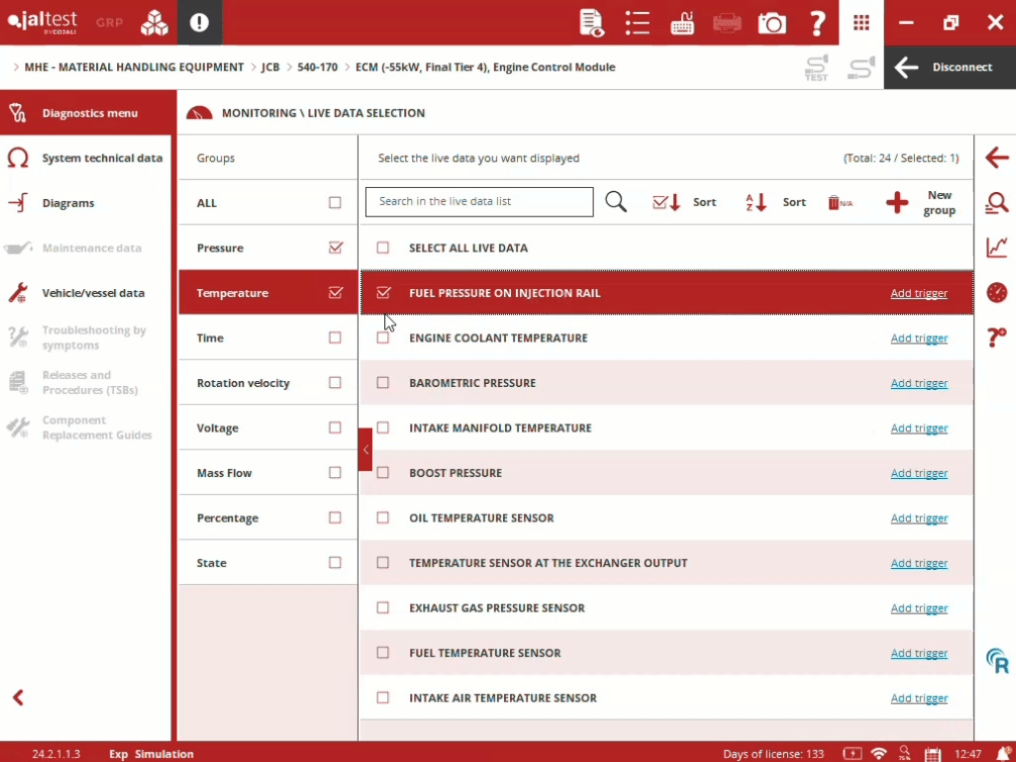

A crucial function of the JCB fault code finder is monitoring live data to know whether all systems are performing at peak operation mode for maximum productivity. Getting data in real time and analyzing it is an optimal way to pre-empt any fault that might crop up and take quick corrective action in case it does.

Go to the Diagnostic Menu and Monitoring/Live Data Selection. From the drop-down menu, you can either choose all systems for diagnosis or any one special function. Some of the options are Pressure, Temperature, Time, Rotational Velocity, Voltage, Mass Flow, and more.

Now select one of them, say Temperature, and get several alternatives for real-time diagnosis, including Engine Coolant Temperature, Intake Manifold Temperature, Oil Temperature sensor, and others. There cannot be a more comprehensive diagnostic scanner than the JCB fault code finder.

What makes the JCB fault code stand out from the crowd is the three updates that we offer every year. This takes care of any technological innovations in JCB material handling equipment and prevents our software from becoming obsolete.