Challenger Diagnostic Scan Tool

Challenger is among the leading brands of tractors used extensively across farms in the USA and Canada. Originally created by Caterpillar Inc. in 1986, it was sold to the current owners AGCO Corp in 2002.

The Jaltest Challenger diagnostic scanner is industry-leading software that ensures that your Challenger tractors are continually on the job without downtime. It reads fault codes and identifies them well in time, offering optimized solutions to ensure that minor issues do not blow up into major problems.

The Jaltest Challenger tractor diagnostic tool covers a wide range of Challenger tractors. These include MT400 Series, MT500B/C/D Series, MT600B/C/D Series, and MT700 & MT800 Series (Track Tractors).

Hence, one software can conduct cutting-edge diagnostics across several models of Challenger tractors. You do not have to buy, for instance, the Challenger MT500B or the Challenger MT400 diagnostic tool separately, the main Jaltest Challenger tractor fault code reader is more than capable in this regard.

Apart from the Challenger tractor scan tool, our Jaltest maintenance tool covers other critical machines construction equipment, agricultural equipment, material handling equipment, trucks, marine engines, and others.

Request a Custom Demo VideoDeep Coverage Of Key Control Modules

Our Jaltest Challenger tractor diagnostic maintenance tool offers maximized support to key control modules. Among the systems and components covered are the Instrument Panel, Transmission Control Unit (TCU), Armrest and Joystick Controls, Hitch and Hydraulic Control Systems, Air Conditioning Module, and more.

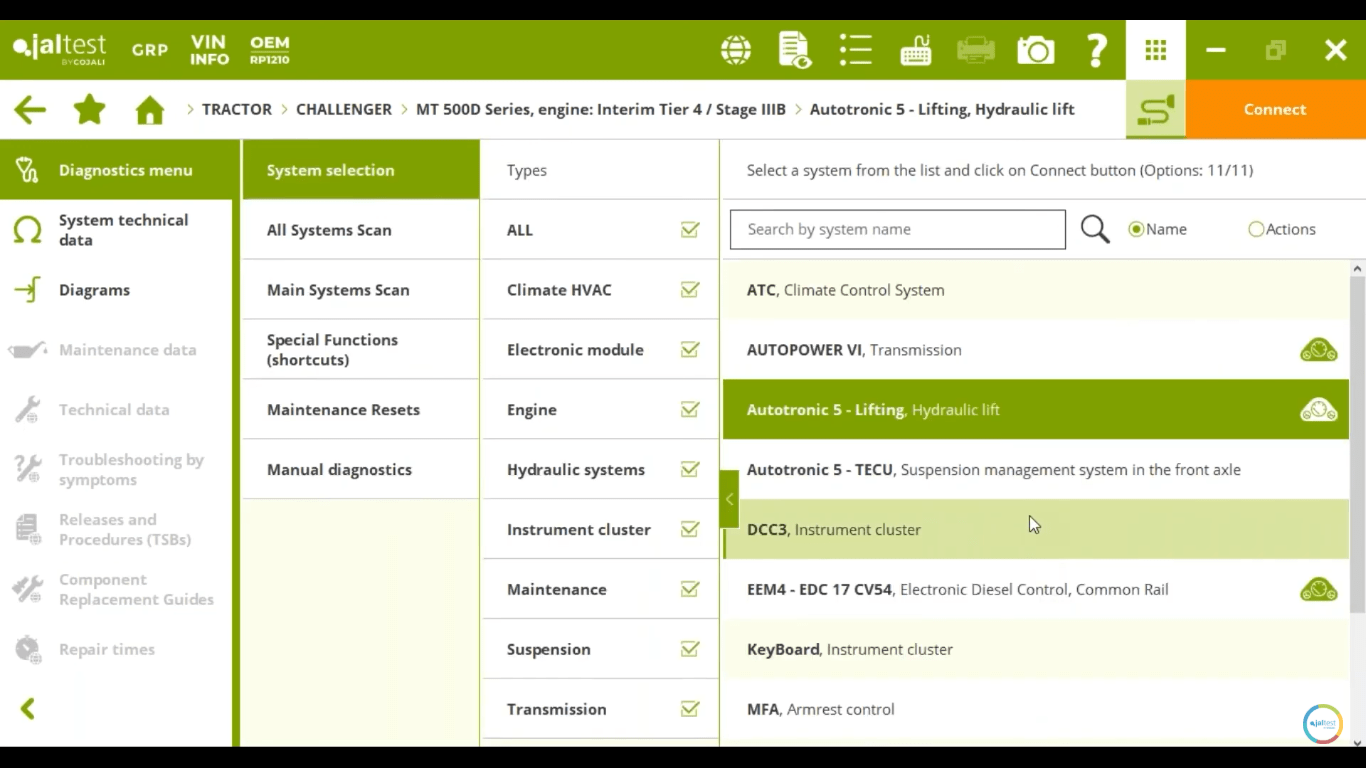

When you access the Challenger tractor diagnostic software, you can either go for all system scans to check for any issue or scan systems by symptoms whenever a fault code crops up. If you click on ALL, you get the systems to be scanned from the dropdown menu. Among them are Climate HVAC, Electronic Modules, Engines, Hydraulic Systems, Instrument Clusters, and other systems.

For each of these modules, the software displays various parameters for analysis. For example, under the Hydraulic System, there is a suspension management system in the front axle. Nothing is left to chance in the Jaltest Challenger agriculture equipment scanner to keep your Challenger tractors on the job.

Engine and Transmission Diagnostics Of Challenger Tractors

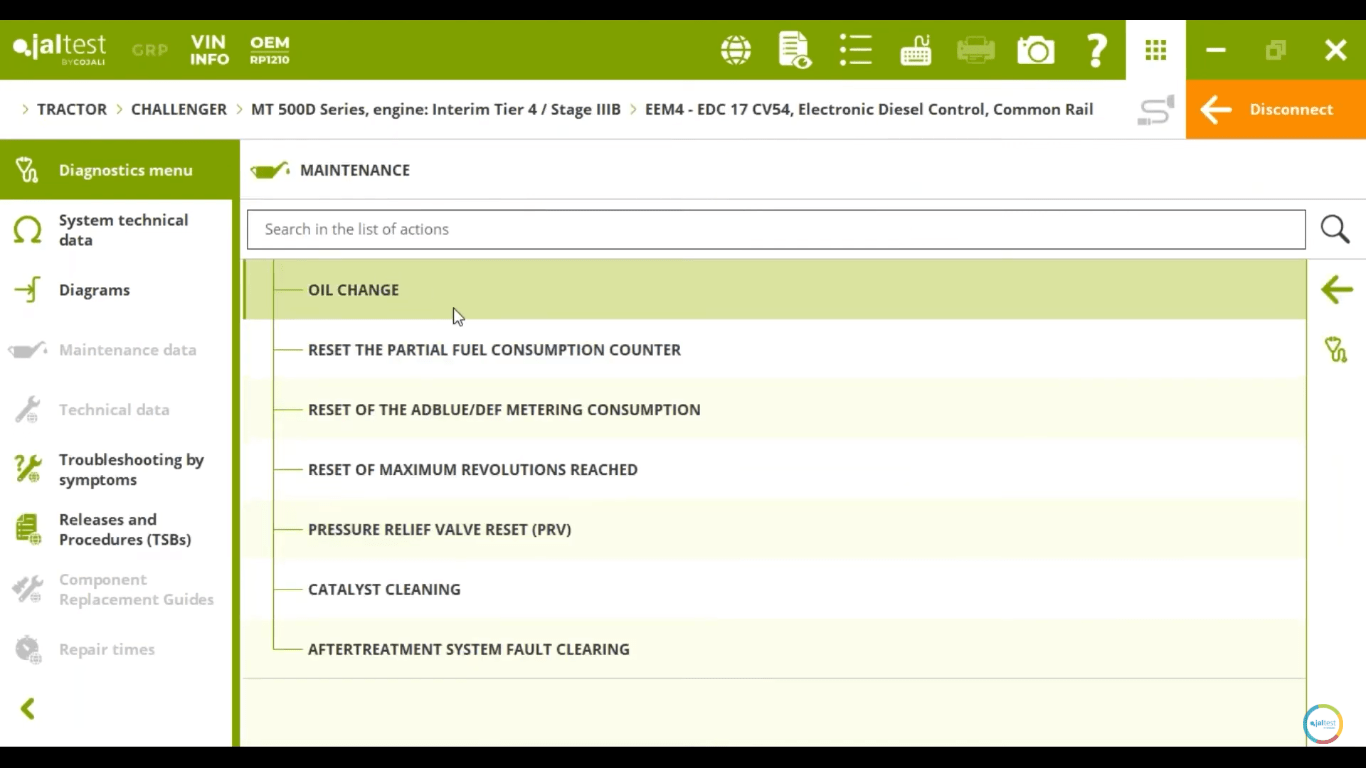

The Jaltest Challenger tractor scanner offers complete diagnostic coverage for the following engine brands: AGCO Power Engines, SISU Diesel Engines, and Select Caterpillar Engines (older MT700–800 series). You can take up simple issues or more complex ones like forced regens.

Let us take the case of the Caterpillar engine diagnostic scanner and its role in forced regens for Caterpillar engines in Challenger tractors. When soot accumulates in the Diesel Particulate Filter (DPF), the engine performance drops drastically, and in severe cases, the tractor might go into limp mode. The Jaltest tool will help you to identify the fault and guide you through the resolutions for Challenger tractor DPF filter cleaning.

Another key component that is covered by our Challenger diagnostic tool is transmission. These are the TechStar CVT (Continuously Variable Transmission) and TechStar CVT (Continuously Variable Transmission). Use our Techstar CVT Transmission fault code reader or the Challenger Powershift transmission diagnostic tool to keep your Challenger tractors always in working mode.

Fault Code Clearing With Challenger Tractor Diagnostic Scanner

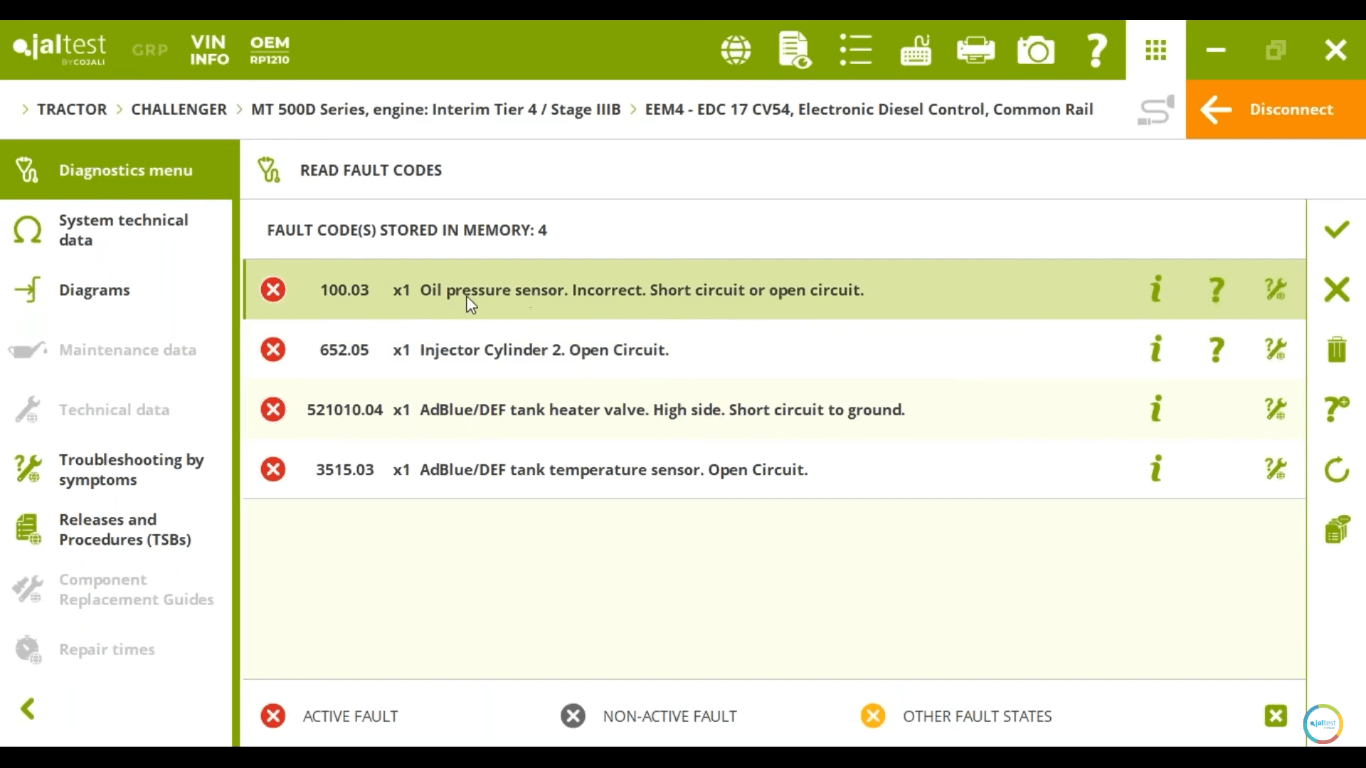

Diagnosing and clearing fault codes are the main functions of the Jaltest Challenger agricultural equipment scan tool. Whenever a fault code is shown on the display screen of the tractor inboard computer, connect our diagnostic software laptop to it to check the problem and what resolution will clear it.

Here are some examples to illustrate fault code numbers and how they will be shown in the Jaltest software.

100.03: Oil pressure sensor, short circuit, or open circuit

652.05: Injector cylinder 2. Open circuit

521010.04: AdBlue/DEF tank heater valve, high side, short circuit to the ground

Similarly, other fault codes support all systems and components of your Challenger tractors. Once the fault is identified, the software will guide you through the required solution that is no less than what is offered by dealers and service engineers.

How to Use The Challenger Agriculture Equipment Diagnostic Tool

While the Jaltest Challenger tractor diagnostic tool is very user-friendly, you must follow the usage guidelines to get optimized cutting-edge diagnosis and resolutions of fault codes.

Let us look at how to use the diagnostic software for best and error-free results.

• Use the appropriate cable to connect the software laptop to the onboard computer.

• Verify that the pins of the diagnosis connector and the cables are not damaged.

• Guarantee the electrical supply of the vehicle, the system, and the diagnostic device. The vehicle battery should be in perfect working condition.

• You should avoid connecting the diagnostic device with a moving vehicle.

Once these basic conditions are met, you are ready to use the Jaltest Challenger tractor computer scanner for fault code analysis and clearance.

When you use the Jaltest Challenger tractor diagnostic scanner, you get three upgrades to the software every year. This is to ensure that our diagnostic tool is in sync with technical innovations in Challenger tractors and that no new systems and components fall outside the ambit of our software.