Cummins Engine Diagnostic Scan Tool

Cummins is a world leader when it comes to industrial engines. They are reliable, technologically advanced, and ideal for a range of applications across various sectors. Cummins is an American multinational company, known for designing and manufacturing engines, filtration, and power generation equipment.

Additionally, the main Cummins Engine Business Unit offers aftermarket support as well as mid-range, heavy-duty, and high-power engines. Cummins engines are used in a variety of applications in several sectors. Let us take a few examples.

Even though Cummins is renowned as an engine maker, the company has also diversified into trucks and heavy-duty commercial vehicles, fuel systems, emission control, air handling, electrical power generation systems, and more.

For owners of Cummins engine-powered equipment and its service centers, the Jaltest Cummins diagnostic software is an essential tool to provide optimized fault rectification solutions. It is a cutting-edge tool that is designed for Cummins industrial engines, with which technicians can perform key service activities that are no less than dealer-level standards.

Among the key activities that can be carried out with the Jaltest Cummins scan tool are monitoring live measurement data, assessing technical information, reading and clearing fault codes, and calibrating components. With such an optimized tool, it is possible to quickly identify any malfunctions and troubleshoot them, thereby making sure that engines are always in peak performance mode.

Apart from Cummins engines, the Jaltest scanning and diagnostic software is also available for other applications. These are commercial and construction equipment, material handling equipment, and more.

Request a Custom Demo VideoFeatures of the Jaltest Cummins Diagnostic Tool

Fault code identification and quick resolutions

Live measurements and real-time parameter monitoring

Component actuation for key systems

Guided repair through detailed wiring diagrams

Maintenance and service resets

Technical information for operational data

Jaltest Diagnostic Solutions for Industries

Construction & Heavy Equipment Diagnostic Software

Marine Diagnostic Software

Commercial Truck Diagnostic Software

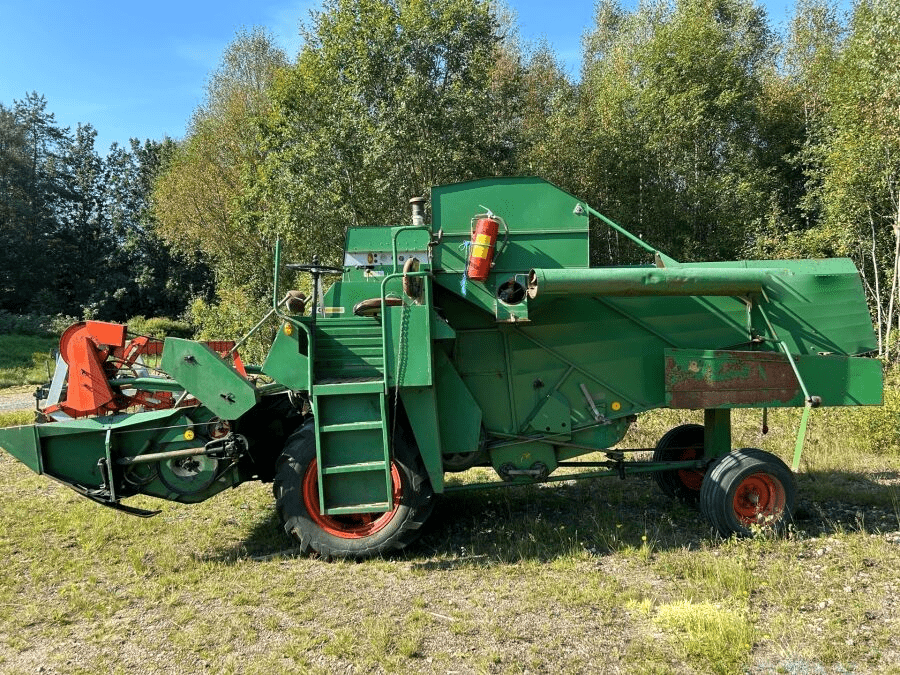

Agriculture Equipment Diagnostic Software

Wide Coverage of Cummins Diagnostic Scanner

When you invest in the Jaltest Cummins diagnostic scanner, you get access to advanced diagnostics across a wide range of Cummins engines.

Cummins QSB6.7: Commonly used in medium-duty construction equipment (excavators, loaders, skid-steers), material handling machinery (forklifts, telehandlers), and small industrial generators.

Cummins QSL9: Commonly used in heavy-duty construction equipment (large excavators, dozers, dump trucks), material handling equipment (forklifts, cranes), and large generators for high-power applications.

Cummins QSB7: Commonly used in water pumps, air compressors, generators, tower lights, and more - oil and gas industry in fracturing pumps

Hence, the Jaltest Cummins engine code reader is a one-stop diagnostic tool across a range of Cummins engines. It functions equally efficiently as a Cummins QSB6.7 diagnostic tool, a Cummins QSL9 diagnostic scanner, and a Cummins forklift/telehandler/loader engine scan tool.

User-Friendly Diagnostic Menu for Easy Navigation

The Jaltest Cummins engine diagnostic scanner has a user-friendly diagnostic menu that helps you to easily navigate through the various complexities of fault code clearance. Along with the diagnostic menu, you get maintenance and vehicle data, detailed diagrams to know the precise location of the fault, and steps for troubleshooting by symptoms.

Under the diagnostic menu options, there is a host of actions that can be taken depending on the nature of the fault. For example, you can expand the Cylinder cut-out test to include checks on the fuel system, the VGT actuator, and the test mode on roller bench. Similarly, for fault code clearance on the aftertreatment fuel system, there is the intermittent connection test of switches and sensors, and the engine status monitor.

When you use our Jaltest Cummins engine scanner, you are assured of optimized diagnostics, regardless of the model of the Cummins engine.

Getting The Most From the Jaltest Cummins Diagnostic Software

The Jaltest Cummins diagnostic scan tool is an optimized software that guides you through the most complex fault code clearing activities. Further, all systems are covered along with component replacement guides.

An example will illustrate this point better. If a fault code indicates an issue with the exhaust gas pressure sensor, the diagnostic menu will advise you on how to remove, check, and reinstall the component. In case it needs to be replaced, the component replacement guide will take you step-by-step through the entire procedure.

Again, consider the monitoring of the exhaust gas system. Once you connect the Jaltest Cummins diagnostic tool to the onboard computer and track the aftertreatment system, you will be shown the extent of soot content in the Diesel Particulate Filter. Based on the data, you can carry out forced regens to clear the DPF, prevent the engine from going into limp mode, and boost its performance.

Cummins Engine Fault Code Clearance

The Jaltest Cummins code reader analyzes fault code alerts that are sent on the onboard computer to warn you that something is not right with the engine, and quick action is required. These are alphanumeric messages and can mean anything from a simple error to a complex one that may require downtime and stoppage of work.

For example, the Cummins engine fault code 1117 indicates a lost power supply with the ignition on. Possible causes are a faulty battery, damaged wiring harness, faulty ECM, or corroded or loose battery connections. The Cummins engine fault code 1569 is “Engine Protection Torque Derate,” which means the engine is reducing power due to a detected issue.

The Cummins diagnostic software is easy to download and install on the Jaltest laptop, and unlike other software in this niche, it does not require any elaborate configuration or setup processes. Further, we offer three updates to the software every year. This is to keep it in sync with any technological innovations made to Cummins engines and to prevent the scan tool from becoming obsolete.