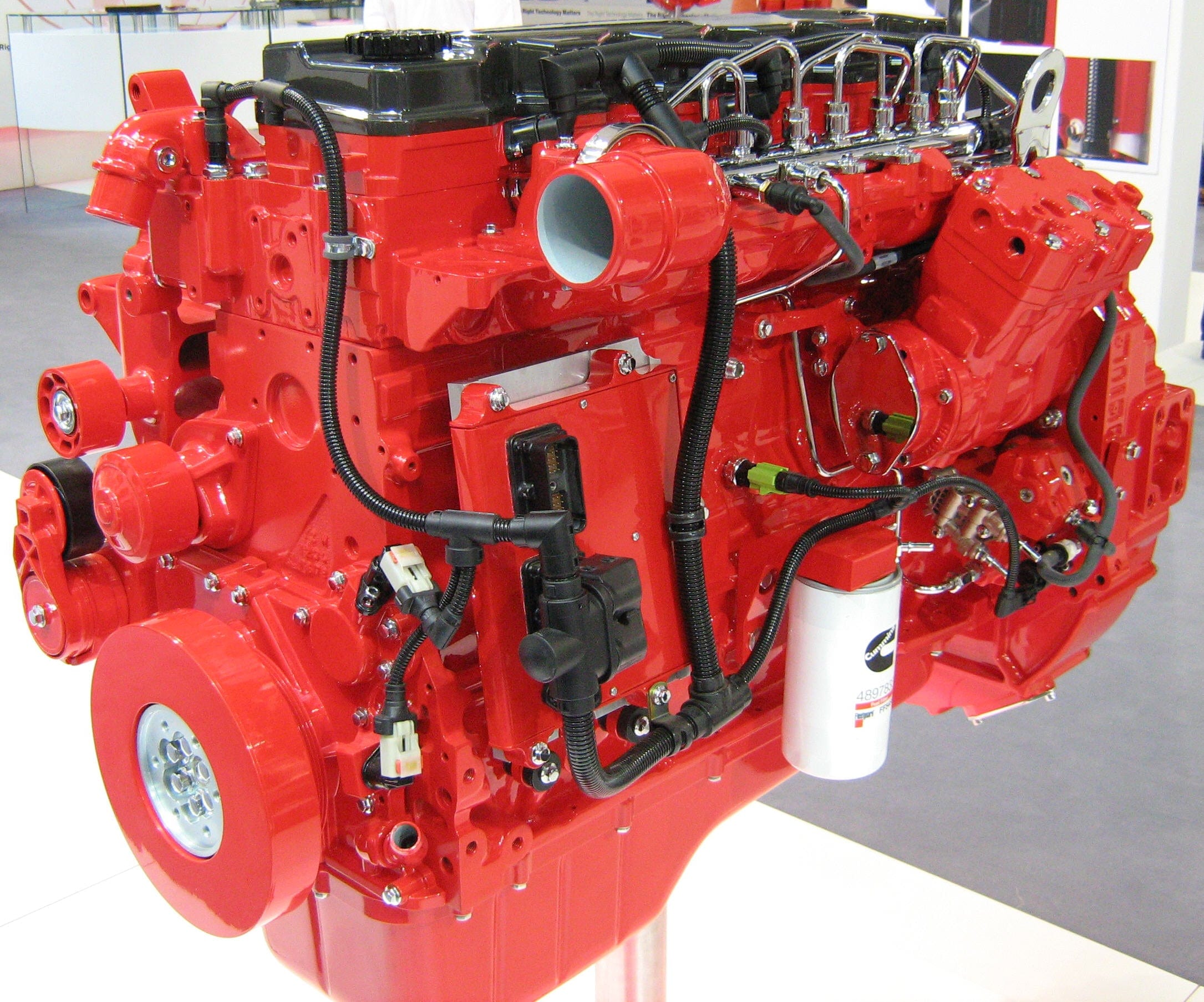

When you talk of engines used for reliable and technologically advanced heavy-duty applications, Cummins is the first name that pops to mind. Cummins is an American multinational company and a leader in designing, manufacturing, and designing engines, filtration, and power generation equipment.

There is hardly any sector that Cummins has not touched upon. In heavy construction and material handling equipment, Cummins engines power excavators, forklifts, cranes, graders, rollers, drillers, and crushers in industrial applications. In transport, Cummins engines are used in heavy-duty pickups and Chassis Cab trucks, the most notable being the Ram 2500, 3500, 4500, and 5500 models.

Cummins is also into power generation and provides engines for generators in stationary power and other electric and hybrid power solutions. Other applications of Cummins engines are in the areas of mining, oil and gas, and defense.

For owners of Cummins-engine-powered equipment and machinery, it is essential to have Cummins diagnostic software to ensure that their project or work is not impaired and they are always on the job.

This post will go into the various aspects of the Cummins diagnostic tool and fault code clearance so that your machinery is always in peak performance mode.

The Function Of The Cummins Diagnostic Software

To understand the functioning of the Jaltest Cummins diagnostic tool, it is necessary to first know what fault codes are since they are resolved with the help of the software.

Every modern vehicle, construction, or material handling equipment has an onboard computer called the Electronic Control Unit (ECU). It indicates the health of the equipment and any malfunction is displayed as fault codes in alpha-numeric format on the display that is generally positioned below the dashboard on the driver’s side.

These fault codes might be minor and temporary and go away within a few driving cycles or more permanent requiring expert rectification solutions. This is where the Cummins engine diagnostic tool has a major role to play in keeping your fleet on the job. It tracks the fault code, interprets what the issue is all about, and offers solutions that prevent any minor problem from becoming a full-blown one.

If the fault code indicates the presence of a serious problem with the need for an overhaul of systems or components, our Jaltest Cummins diagnostic tool makes the process easy and seamless. Simply connect the Jaltest Cummins diagnostic computer to the onboard computer of the vehicle and it will help you identify the fault and handhold you through the process of clearing it.

The Jaltest Cummins diagnostic software is optimized to describe the fault in detail and suggest solutions that are no less than dealer-level ones from certified engineers. The software offers detailed wiring diagrams of the systems so that you can know the precise location of the fault and what are the parts and components that are affected. Once done, you can implement fault-clearing activities to bring your machinery back to work.

Our Jaltest Cummins engine diagnostic tool shows all electronic information on the Jaltest software screen. You are guided in clearing faults through schematic diagrams and engine drawings to make the work simpler for you. With wiring and sensor location diagrams, you can adjust parameters to get the most out of your engine’s performance. With these aids, troubleshooting time is substantially reduced and fault diagnosis processes are streamlined.

A very effective tool in the Cummins diagnostic software niche is the Cummins ISX diagnostic software. The Cummins ISX engine is among the most advanced in the Cummins engines range and is a heavy-duty diesel engine. Our ISX diagnostic software is specially designed to interpret and read the fault code of this engine. You can directly retrieve diagnostic information like error codes and live data and identify and troubleshoot issues within the engine systems.

The Cummins ISX diagnostic software displays live engine data such as coolant temperature and fuel pressure and helps clear fault codes related to engine performance. It also analyzes the possible causes of a malfunction which makes troubleshooting easier.

Click Here

How To Get The Most Out Of Your Cummins Diagnostic Computer

The Jaltest Cummins diagnostic software is a very intuitive and user-friendly maintenance tool that ensures that your Cummins engine runs always at peak operating efficiency. You can carry out both preventive maintenance as well as clearing fault codes whenever they arise.

Let us check out these critical functions in some detail.

The first is preventive maintenance to check the health of the engine even though there is no fault code signal apparent on the display screen of the onboard computer. All that you have to do is connect the Cummins engine diagnostic tool to the ECU and carry out full system scans at pre-determined intervals.

There are two benefits here. One is to check that all systems and components are working as they should and that the engine is performing optimally. The other is to identify any minor issue and work on it before it blows up into a major problem leading to prolonged downtime and delayed projects. Preventive maintenance is a very crucial activity to prevent and solve any issue at its root. It checks whole systems and components such as engines, transmissions, hydraulics, brake lights, HVAC systems, and more.

The second is clearing fault codes whenever they are shown on the display screen of the onboard computer. At this stage, the Jaltest Cummins diagnostic tool must be connected to the ECY, and a scan carried out as per the symptoms and the fault code.

The software will read the fault code and carry out rectification solutions to clear it. You will be prompted to enter the model of the Cummins engine since fault codes are not standardized across all makes and models of equipment and engines. The tool will guide you through the process of bringing your engine to perform at optimum power.

The inbuilt component replacement guide is a very critical feature offered in the Jaltest software. If a component malfunctions, the software will inform you whether it needs to be replaced or repaired. If replacement is necessary, the tool will help you to navigate how it should be done.

While fault-clearing activity is important, no less is preventive maintenance as it pre-empts any major fault from developing.

Read more about Cummins engine fault codes and diagnostic software.

Cummins Diagnostic Software And Fault Codes

We have seen in detail the role of the Jaltest Cummins engine diagnostic tool and how it identifies and clears fault codes. Now, let us go through a few examples of Cummins engine fault codes and what they indicate.

The sequence given here is the fault code, the color of the light on the onboard computer, and the interpretation of the fault code.

- 111 (Red): Engine Control Module – Critical internal failure

- 112 (Red): Engine Timing Actuator is not responding to ECM commands

- 113 (Yellow): Engine Timing Actuator Circuit - shorted high

- 114 (Yellow): Engine Timing Actuator Circuit - shorted low

- 115 (Red): Engine Speed/Position Sensor Circuit - lost both two signals from the magnetic pickup sensor

- 116 (Red): Fuel Timing Pressure Sensor Circuit - shorted high

- 117 (Red): Fuel Timing Pressure Sensor Circuit - shorted low

- 118 (Yellow): Fuel Pump Delivery Pressure Sensor Circuit - shorted high

- 119 (Yellow): Fuel Pump Delivery Pressure Sensor Circuit - shorted low

- 121 (Yellow): Engine Speed/Position Sensor Circuit - lost one of two signals from the magnetic pickup sensor

- 122 (Yellow): Intake Manifold Pressure Sensor #1 Circuit - shorted high

- 123 (Yellow): Intake Manifold Pressure Sensor

Our Jaltest Cummins diagnostic tool not only detects the fault codes but also navigates users through rectification processes that bring the equipment to top operating mode.

Cummins Diesel Diagnostic Software And Forced Regens

Forced regens is an activity that is exclusive to diesel engines. It is required when the Cummins diesel diagnostic software detects high soot accumulation in the Diesel Particulate Filter because passive regens have been unable to clear it. In severe cases of soot buildup, the engine might even seize up and go into limp mode.

Soot buildup occurs when the engine has a stop-go-stop routine that is generally seen in construction equipment such as dozers and excavators and not in long-haul trucks and buses. The fault code for soot accumulation in DPF is SPN 3712 which means that the ECM has limited engine power to facilitate a forced regen cycle. This code also shows up in cases of clogged DPF, faulty DPF sensors, problems with exhaust gas recirculation (EGR), or low-DEF levels.

After the Jaltest Cummins diagnostic software identifies the issue, it suggests optimized solutions that are generally to run the engine on high rev for around 40 minutes. The rise in exhaust gas temperature burns away the built-up soot. Our software will also guide you on clearing related problems such as replacing faulty sensors, cleaning the DPF, or addressing troubles with the EGR system.

Summing Up

Our Cummins diagnostic software is optimized to keep Cummins engine-powered vehicles, equipment, and machinery on the move without breakdown and downtime that may affect project deadlines. The user-friendly tool provides cutting-edge solutions that are at par with dealer-level services.

What makes our software a notch above the competitors is the ease with which it can be set up. There are no elaborate configuration processes, unlike others in this niche. Simply download the software onto your laptop, plug it into the onboard computer and you are ready to start fault reading and clearing procedures. This makes our software so user-friendly and easy to navigate.

Finally, for the convenience of users, we provide three updates to the software every year. This ensures that any innovations and developments made to Cummins engines are covered by our Cummins diagnostic tool and the software never becomes obsolete.

Leave a comment